Introduction to Resin 3D Printing

Stereolithography

It all began in the 1980's when the first printing technology was created - stereolithography. It's a form of 3D printing technology used for creating models, prototypes, patterns, and production parts in a layer by layer fashion using photochemical processes by which light causes monomers and oligomers to cross-link together to form polymers. In other words, it is about converting a liquid plastic into solid objects. However, understanding the principle of SLA helps to understand the main differences between two other methods of printing : DLP and LCD.

So, Stereolithography (SLA) works by curing resin with UV laser. The UV laser solidifies a liquid resin layer by layer. A vat or tank contains the resin which is cured against a build platform. It thereafter slowly rises out of the tank as the object is formed.

With a Digital Light Processing (DLP) technology on the other hand, a digital light projector cures a whole layer at the time . Images of whole layers are flashed onto the bottom of the vat. Layers generated using DLP 3D printers are made up of voxels, the 3D equivalent of pixels. Indeed, in this case, the projector screen itself consists of pixels.

As for LCD 3D printing, it does not have the reputation of the two others. There is not a big difference between LCD and DLP. This technique uses LCD screen as a mask that exposes complete layers at the resin tank. However, in this case, the UV light comes from an array of LEDs and no special device is required to direct the light as it is with the previous ones.

DENTAL

With an ability to print bio-compatable structures for inter-oral use you can print:

- dental crowns & bridges;

- custom trays

- surgical guides

- total & partial dentures

- castable frameworks

- master models

- aligners

- model with removable dies

- gingiva parts

- night guards & splints

JEWELRY

CAD/CAM software allows to print custom jewelry prototypes with alterations in size, pattern and fit for a perfect fit and a satisfied customer.

Small, medium and large elements with very precise details can be printed using wax-like resin to be later casted with metal, cuttng time in manual labour.

Next step would be creating master patterns for rubber molds for wax models for investment casting. Any standart resin will suffice for cold molding and heat-resistant resins for natural rubber molds.

ENGINEERING

- all purpose prototypes

- showpieces

- jigs & fixtures

- form & fit models

- inserts

- pre-production units

- master molds for silicone, plastics

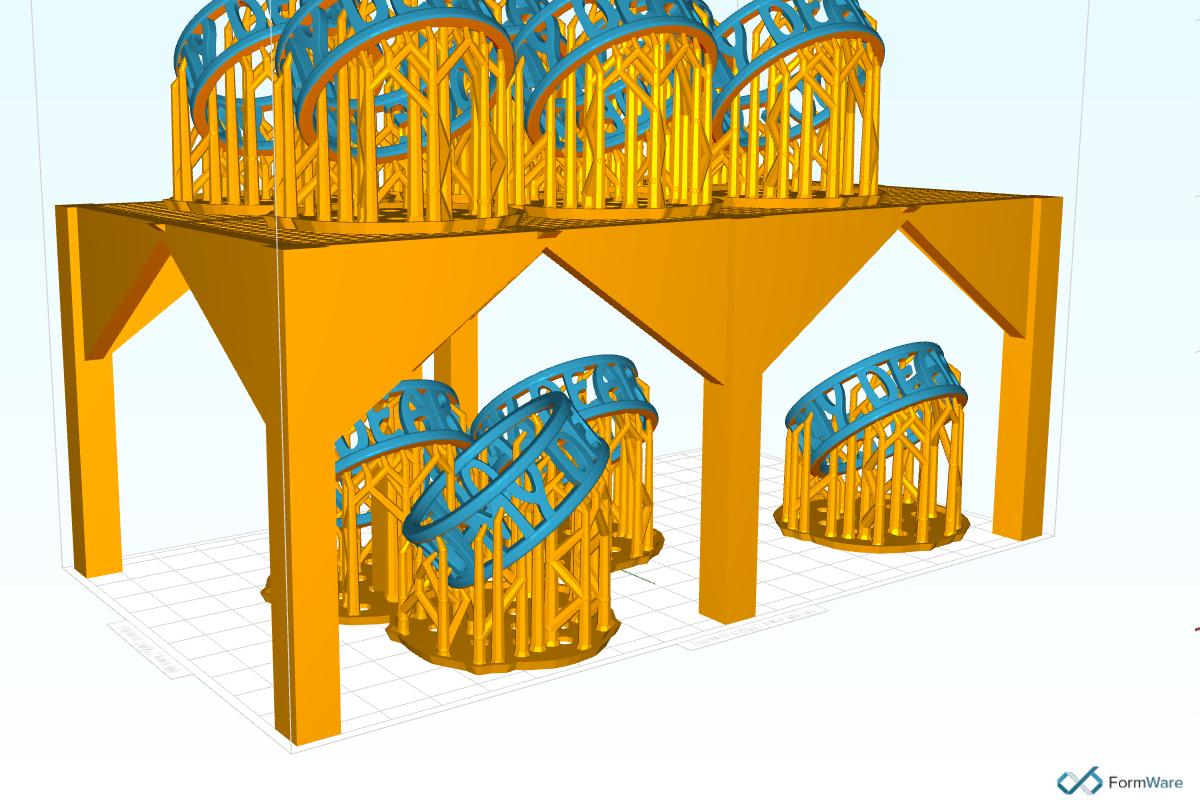

PARTS MANUFACTURING

Big printing volume, expanding choice of resins, multi-layered structures for maximum efficiency. Bring rapid, cost-effective production of jigs, fixtures, and tooling in-house to save money on outsourcing to an external vendor.Drastically cut in :

- production time

- costs per manufatured part

- costs in tooling

- manual labour

ARTIST & ENTHUSIASTS

Turn your digital models into reality. Print, robust, varicolored, highly detailed models of :- busts

- character figures

- toys

- props

Being professional artist, prop-maker, sculptor or just an creative enthusiast - everybody can archieve same results.